The old adage, “It never gets any easier, you just get faster,” is no truer than in the niche world of competitive hill climbing. Joe Norledge from Bristol is one of those masochists who loves to take part in these lung busting, lactate inducing events that take place at the end of the cycling season. For 2016 he thought he’d go even faster if he did it on a fixed gear bike.

Photo by Matt Grayson http://www.mattgrayson.co.uk instagram.com/mattgrayson_photo/

That may sound extreme but, traditionally, hill climbs were often ridden on fixies in an attempt to shave as much weight off the bike as possible. Chris Boardman was three times hill climb champion from 1989-1991 on a fixed gear. And, with a tradition going back to 1887, when the Catford CC climb held its inaugural competition, before the derailleur was ever invented, that’s hardly surprising. Interestingly enough, the fourth placed rider that year did it on a penny farthing.

While Joe wanted something a little more sophisticated than that, he was after a bike that was as light and responsive as it could possibly be. As he says, “Hill climbs are a pretty simple affair. You find a hill. Usually it’s going to be pretty short and steep. You see who can ride up it the fastest…I love it.” Joe’s desire for a fixed gear to compete in the Nationals last year reflects that simplicity. He was aiming for a top 20 finish.

He also wanted a bike that looked good and handled well beyond a hill climb.

He approached Engineered Bicycles in Bristol to make his dream bike, a company set up four years ago by David Fong. It was exactly the kind of project they love doing with their ethos of designing bikes without any superfluous details in their quest to make the best possible machine they can. It was designing a bike that was specific for a specialist purpose and it meant they would have to think beyond the conventional and stretch the grey matter to achieve it.

It had to be light but also maintain good stiffness for good driving efficiency but keeping the handling of the bike sensible so that it worked in the real world. They used a scandium aluminium alloy for the frame. The material allowed them to use thinner wall thickness than a standard alloy. They joined the tubes with a double pass weld that is smoothed down by hand. It’s a long and arduous process but it makes the weld stronger by removing all the little rifts and valleys which can weaken a weld. As a result it looks really good too.

They also saved weight by using a carbon seat tube, instead of aluminium. Joe collected a range of parts that were so light that the finished bike came in at 5.1 kg. That’s including pedals. While it’s possible to do that with a geared, carbon bike, you’d be spending an awful lot more than what Joe spent.

Such a bike needed a beautiful look too. In the old days, people would shave weight off their bike by drilling little holes into the frame to make it lighter. In a homage to this practice, they decided on a pattern that looked as if someone had indeed drilled little holes in the same way that was the age old technique. They avoided painting or lacquering the frame which would add weight by using a head blaster to achieve the effect. The end result was indeed an object of beauty that would not look out of place in a museum.

Photo by Matt Grayson http://www.mattgrayson.co.uk instagram.com/mattgrayson_photo/

Joe picked up his bike as soon as it was finished and took it straight out onto the road. Immediate impressions were that he loved hearing the hum of rubber on tarmac and nothing else. It was his first ever ride on a fixed gear and, while he loved it on the hills and flat, it was alarming having to spin at such a high cadence on the downhill stretches with traffic around and only a front brake to slow down.

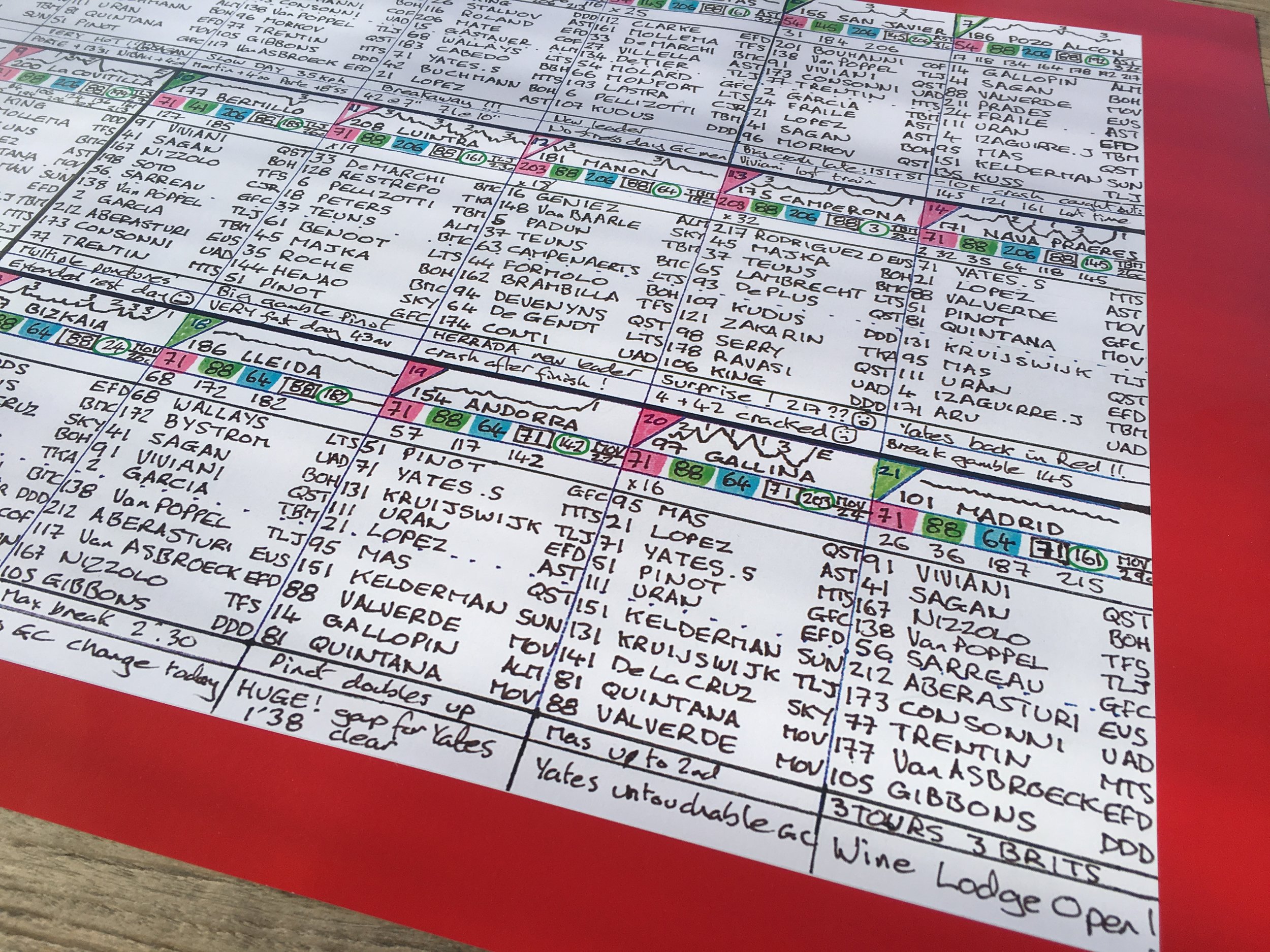

With a scientific eye he began to work out what size gear to use on specific climbs, opting for a 15/22 combination that would enable him to spin a cadence from 60 to 120 rpm on Bank Road in Matlock where the Championships were to be held that year.

He used the bike for everything between August and the end of October to get used to it. He found that he could get around mostly everywhere in Bristol and the surrounding area without any recourse to gears.

And so it came to the end of October and the big day itself. It was the usual scene of big crowds, cheering and cow bells – the classic hill climb atmosphere. Joe reckoned he got his gear calculations about right and was pleased to come in 19th overall, just within his top twenty goal. Nice one, Joe!

You can follow the whole story of Joe’s fixed gear journey on Bike Radar’s video below.